What Is a Weld Neck Flange? The Definitive Guide to Structural Integrity

When strength, pressure containment, and long-term reliability are critical, certain piping components stand out for their structural performance. One of the most trusted flange types in demanding industrial systems is the weld neck flange.

So, what is a weld neck flange?

A weld neck flange is a type of pipe flange specifically designed to be butt-welded directly to a pipe, featuring a long, tapered hub (neck) that reinforces the connection and distributes stress evenly. This design makes it ideal for high-pressure, high-temperature, and cyclic loading applications where structural integrity is essential.

What Is a Weld Neck Flange? (Technical Definition)

A weld neck flange is a forged flange with a protruding, tapered hub that transitions gradually into the pipe wall thickness. It is permanently attached to piping through a full-penetration butt weld, creating a strong, continuous metal structure between the pipe and the flange.

The long tapered neck serves two critical functions:

-

Reinforces the connection

-

Reduces stress concentration at the base of the flange

Because of this structural design, weld neck flanges are widely used in systems that experience:

-

High internal pressure

-

Extreme temperature fluctuations

-

Mechanical vibration

-

Repeated thermal expansion and contraction

Key Design Features of a Weld Neck Flange

Understanding what a weld neck flange is requires examining its defining structural elements.

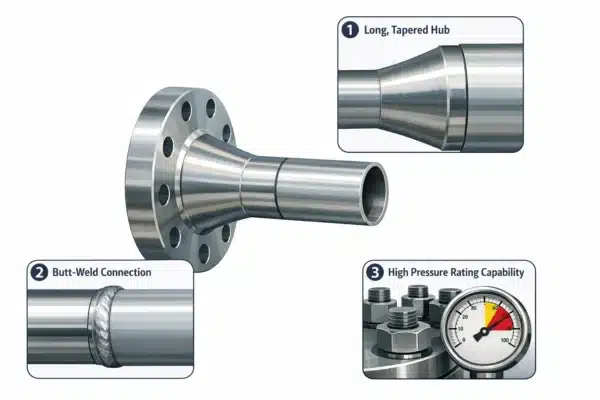

1. Long, Tapered Hub

The most recognizable feature is the extended hub that gradually tapers from the flange face to the pipe diameter. This taper:

-

Provides gradual stress transition

-

Minimizes turbulence at the weld joint

-

Improves fatigue resistance

2. Butt-Weld Connection

Unlike slip-on or threaded flanges, weld neck flanges are attached using a butt weld, meaning the pipe and flange are welded end-to-end. This method:

-

Creates a seamless flow path

-

Enhances strength

-

Reduces the risk of leakage

3. High Pressure Rating Compatibility

Weld neck flanges are manufactured in multiple pressure classes (e.g., 150, 300, 600, 900, 1500, 2500) and are commonly used in high-pressure service environments.

Why Weld Neck Flanges Are Used in High-Pressure Applications

One of the primary reasons weld neck flanges are selected is their ability to handle extreme pressure conditions.

The tapered hub distributes mechanical stress across a broader area rather than concentrating it at the flange base. This reduces the likelihood of:

-

Cracking

-

Warping

-

Structural failure

In critical systems such as oil and gas processing, petrochemical plants, and power generation facilities, this reinforcement is essential for maintaining safe operation.

Performance in High-Temperature Environments

Temperature fluctuations can cause metal expansion and contraction, placing repeated stress on piping connections. The structural continuity created by the butt weld and tapered hub allows weld neck flanges to perform reliably under:

-

Elevated process temperatures

-

Thermal cycling

-

Steam service

-

High-heat industrial systems

This makes them a preferred choice in refineries, boiler systems, and heavy industrial processing facilities.

Comparison to Other Flange Types

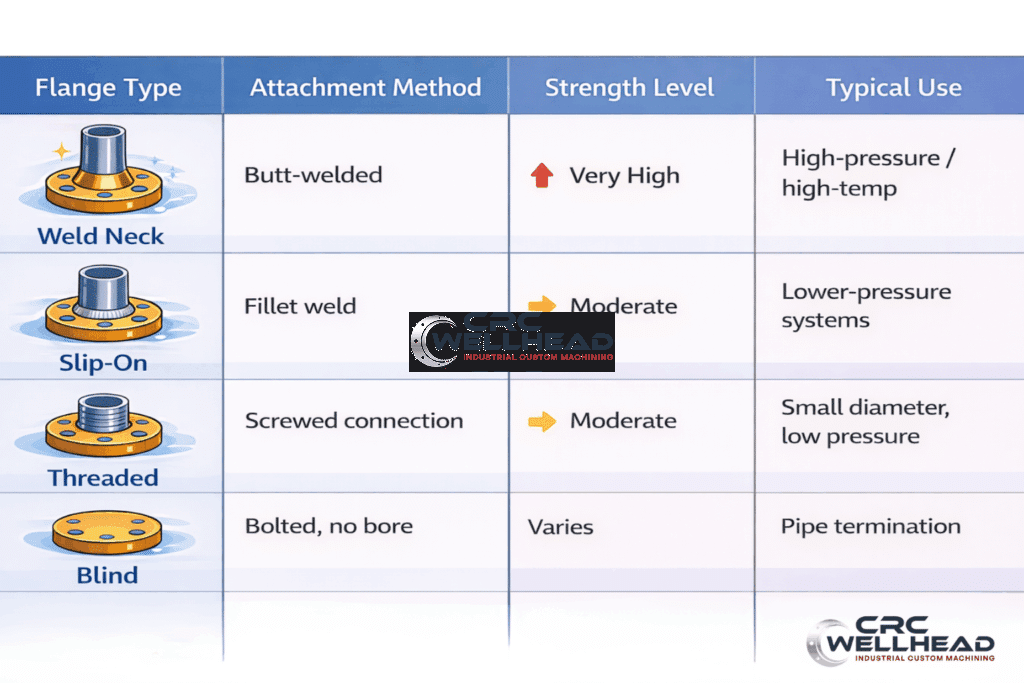

To better understand what a weld neck flange is, it helps to briefly compare it to other common flange types.

Among these options, the weld neck flange offers the highest structural integrity, especially for critical service lines.

Materials Used in Weld Neck Flanges

Because weld neck flanges are often installed in demanding environments, material selection is crucial. Common materials include:

-

Carbon steel

-

Stainless steel

-

Alloy steel

-

Duplex stainless steel

Material choice depends on pressure ratings, corrosion exposure, and operating temperatures.

Benefits of Using a Weld Neck Flange

Choosing a weld neck flange offers several operational advantages:

-

Superior strength and durability

-

Improved fatigue resistance

-

Reduced leakage risk

-

Smooth internal bore alignment

-

Enhanced long-term reliability

For systems where failure is not an option, this flange design provides added safety margins.

When Should You Use a Weld Neck Flange?

Weld neck flanges are typically specified when:

-

System pressure is high

-

Temperature exceeds standard operating ranges

-

The application involves vibration or cyclic loading

-

Safety and regulatory compliance are critical

-

Long service life is required

Although they may require more precise installation and welding procedures, their durability often justifies the investment.

Precision Machining and Quality Control

The performance of a weld neck flange depends heavily on machining accuracy. Proper tolerances ensure:

-

Accurate bore alignment

-

Secure gasket seating

-

Correct bolt hole alignment

-

Reliable sealing performance

Precision manufacturing also ensures compatibility with industry standards and pressure classifications.

What Is a Weld Neck Flange?

So, what is a weld neck flange?

It is a high-strength, butt-welded flange featuring a long, tapered hub designed to reinforce the connection between pipe and flange. Engineered for high-pressure and high-temperature environments, weld neck flanges deliver structural stability, stress distribution, and long-term reliability in demanding industrial systems.

When system integrity is critical, weld neck flanges remain one of the most dependable choices in industrial piping design.

About CRC Wellhead Supply

CRC Wellhead Supply manufactures and machines high-performance industrial components designed for strength, accuracy, and durability. With advanced CNC and manual machining capabilities, CRC delivers precision-engineered solutions built to meet demanding pressure and performance requirements.

Contact CRC Wellhead Supply today to learn more about precision-machined flanges and custom industrial components engineered for reliability.