What Is a Companion Flange? The Essential Link in Industrial Piping

In industrial piping systems, flanges are critical components that allow pipes, valves, and equipment to be connected securely while still permitting disassembly for maintenance or inspection. Among the many flange types used in mechanical and industrial applications, the companion flange plays a unique and essential role.

To properly understand what a companion flange is, it’s important to look at its design, function, and how it differs from other common flange types. This article provides a clear technical explanation of companion flanges and their role in industrial piping systems.

What Is a Companion Flange?

A companion flange is a type of pipe flange designed to mate with another flange in a bolted piping connection. Unlike weld neck or slip-on flanges, a companion flange typically features a threaded hub on the back side, allowing it to be screwed directly onto a pipe instead of being welded.

The threads on a companion flange are commonly:

-

NPT (National Pipe Thread)

-

API threads, depending on system requirements

The front face of the companion flange bolts directly to another flange—such as a blind flange, weld neck flange, or valve flange—creating a secure, sealed connection.

Why It’s Called a “Companion” Flange

The term companion comes from the flange’s purpose: it is designed to work in partnership with another flange. On its own, a companion flange does not complete a connection. Its function is fulfilled when it mates with a matching flange face using bolts and a gasket.

This pairing allows for:

-

Easy assembly

-

Secure sealing

-

Simple disassembly when required

Key Design Features of a Companion Flange

Understanding what a companion flange is also requires examining its physical characteristics.

1. Threaded Hub

The defining feature of a companion flange is its internally threaded hub, which connects directly to a threaded pipe. This eliminates the need for welding.

2. Standard Flange Face

The front face is machined to mate with another flange, typically using:

-

Flat face

-

Raised face

The face type must match the mating flange to ensure proper sealing.

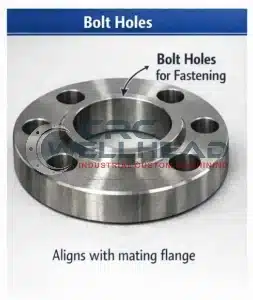

3. Bolt Holes

Bolt holes align with the mating flange, allowing the two components to be securely fastened together using studs or bolts.

What Is a Companion Flange Used For?

Companion flanges are commonly used in industrial systems where welding is impractical, undesirable, or restricted. Typical uses include:

1. Threaded Pipe Connections

Companion flanges are ideal for threaded piping systems, allowing the pipe to be connected without welding. This is especially useful in:

-

Temporary installations

-

Low to moderate pressure systems

-

Maintenance-sensitive environments

2. Equipment and Valve Connections

They are often used to connect:

-

Valves

-

Pumps

-

Instruments

-

Mechanical equipment

The threaded connection allows easier removal or replacement of components without cutting or welding the pipe.

3. Maintenance and System Access

Because companion flanges can be unbolted and unscrewed, they provide convenient access for:

-

Inspection

-

Cleaning

-

Repairs

-

System modifications

This makes them valuable in facilities that require frequent maintenance.

Advantages of Using a Companion Flange

Companion flanges offer several benefits in industrial piping systems:

-

No welding required

-

Faster installation

-

Easier disassembly

-

Reduced downtime during maintenance

-

Suitable for threaded piping systems

-

Cost-effective for certain applications

These advantages make them a practical choice for many mechanical systems.

Limitations of Companion Flanges

While companion flanges are versatile, they are not suitable for every application. Limitations include:

-

Less ideal for very high-pressure systems

-

Threaded connections may loosen under vibration

-

Not recommended where welding strength is required

Proper application and engineering judgment are essential when selecting flange types.

Materials Commonly Used for Companion Flanges

Companion flanges are manufactured in various materials to suit different environments, including:

-

Carbon steel

-

Stainless steel

-

Alloy steel

-

Specialty industrial materials

Material selection depends on operating pressure, temperature, and exposure conditions.

Why Companion Flanges Matter

So, what is a companion flange? It is a threaded flange designed to mate with another flange, providing a reliable, removable connection in industrial piping systems. With its threaded hub and bolted face, the companion flange offers flexibility, ease of installation, and convenient maintenance access.

When used in the right application, companion flanges are an essential link that supports efficient system design, safe operation, and long-term reliability in industrial and mechanical piping networks.

If you require high-quality companion flanges or custom-machined piping components, CRC Wellhead Supply offers Canadian-made solutions backed by decades of experience, precision CNC machining, and strict quality standards.

Contact CRC Wellhead today to discuss your application or request a custom machining quote.