Types of Cutting Tools for Milling Machines: A Complete Guide

Milling machines are essential in modern machining, used to cut, shape, and finish solid materials. But to get precise results, the right cutting tool must be used. Each milling operation requires a specific tool designed for that task, making the selection of cutting tools a critical decision.

In this guide, we’ll explore the most common types of cutting tools for milling machines, their features, and their best use cases.

What Are Milling Machine Cutting Tools?

Cutting tools for milling machines are rotary tools used to remove material from a workpiece. They come in different shapes, sizes, and materials depending on the milling operation such as face milling, slotting, contouring, or drilling.

These tools are often made of high-speed steel (HSS), carbide, or cobalt, and can be coated for enhanced durability. Choosing the correct tool improves surface finish, tool life, and machining efficiency.

Common Types of Cutting Tools for Milling Machines

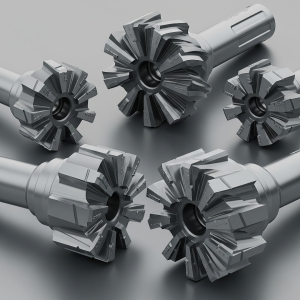

1. End Mills

- Function: Used for general-purpose milling.

- Design: Cutting edges on both the end and sides.

- Uses: Slotting, contouring, profile milling, and plunging.

- Types: Square end, ball nose, and corner radius.

End mills are some of the most commonly used milling cutters. They’re ideal for shaping surfaces and features with high precision.

2. Face Mills

- Function: Used for cutting flat surfaces.

- Design: Large cutting diameter with multiple cutting edges or inserts.

- Uses: Face milling large surface areas quickly.

Face mills are perfect for creating smooth finishes over broad surfaces. They are generally mounted on horizontal milling machines.

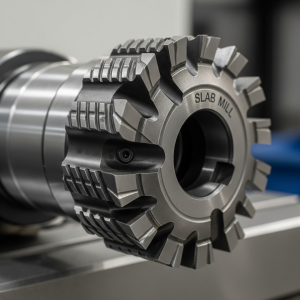

3. Slab Mills

- Function: Heavy material removal.

- Design: Cylindrical cutter with teeth around the periphery.

- Uses: Plain milling on horizontal machines.

These are used when large amounts of material need to be removed efficiently, especially on flat surfaces.

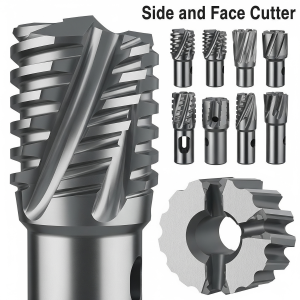

4. Side and Face Cutters

- Function: Cut slots and grooves.

- Design: Teeth on both the side and periphery.

- Uses: Simultaneous face and side milling.

These are ideal for operations that require cutting deeper or wider slots than what an end mill can handle.

5. Ball Nose End Mills

- Function: Create rounded profiles or 3D shapes.

- Design: Rounded tip instead of a flat end.

- Uses: 3D contouring, mold making, and die finishing.

Ball nose cutters are essential for detailed and complex surfaces, such as those in aerospace or mold industries.

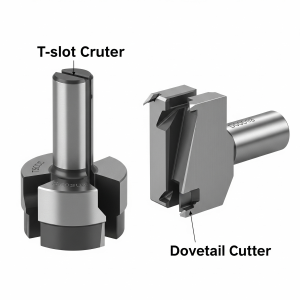

6. T-Slot and Dovetail Cutters

- T-Slot Cutters: Specifically shaped for cutting T-slots used in machine tables or fixtures.

- Dovetail Cutters: Designed to cut angled dovetail grooves.

Both are used to create interlocking joints or specialized slots.

Cutter Materials and Coatings

Milling cutters can be made from:

- High-Speed Steel (HSS): Affordable and good for soft materials.

- Carbide: Durable and heat-resistant; suited for high-speed applications.

- Cobalt Steel: Stronger than HSS; ideal for tough metals.

- Coated Tools: Titanium nitride (TiN), TiAlN, and other coatings enhance tool life and reduce friction.

How to Choose the Right Cutting Tool

When selecting a tool, consider:

- Material of the workpiece (e.g., aluminum vs. stainless steel).

- Milling operation type (slotting, facing, contouring, etc.).

- Machine capability (spindle speed, rigidity, etc.).

- Surface finish requirements (flat vs. 3D profiles).

- Budget vs. tool life (HSS for budget, carbide for durability).

Understanding the different types of cutting tools for milling machines is key to getting accurate, efficient results in any machining task. Whether you’re a beginner or experienced machinist, knowing what each tool is used for helps you choose the right one for the job saving time, money, and effort.

Always consider the tool’s shape, material, and purpose before beginning any milling operation. With the right tool, even complex parts can be machined with precision and confidence. For high-quality milling tools and expert support, Can Star Industrial is your trusted partner in precision machining solutions.