Top 10 Milling Tips and Tricks Every Machinist Should Know

Mastering the art of milling requires more than just operating a machine it takes precision, planning, and practical know-how. Whether you’re in a small workshop or managing high-volume CNC operations, understanding the right techniques can elevate your work from good to exceptional. In this guide, we’ll walk you through the top milling tips and tricks every machinist should know to improve efficiency, extend tool life, and deliver flawless results every time.

1. Know Your Materials and Match the Tool

Different materials behave in unique ways under the cutter. Mild steel, aluminum, stainless steel, and titanium all require different approaches. For example, aluminum cuts best with sharp tools and high speeds, while hardened steels benefit from slower, more deliberate passes and rigid setups.

Tip: Use carbide tools for tough materials and opt for coating options like TiAlN for high-heat applications.

2. Dial in Speeds and Feeds Properly

Getting your speeds and feeds right is critical. Too fast and you’ll wear out your tools or damage the part. Too slow and you might get chatter or a poor finish. Always refer to manufacturer guidelines and use calculators to help determine the best RPM and feed rate for your setup.

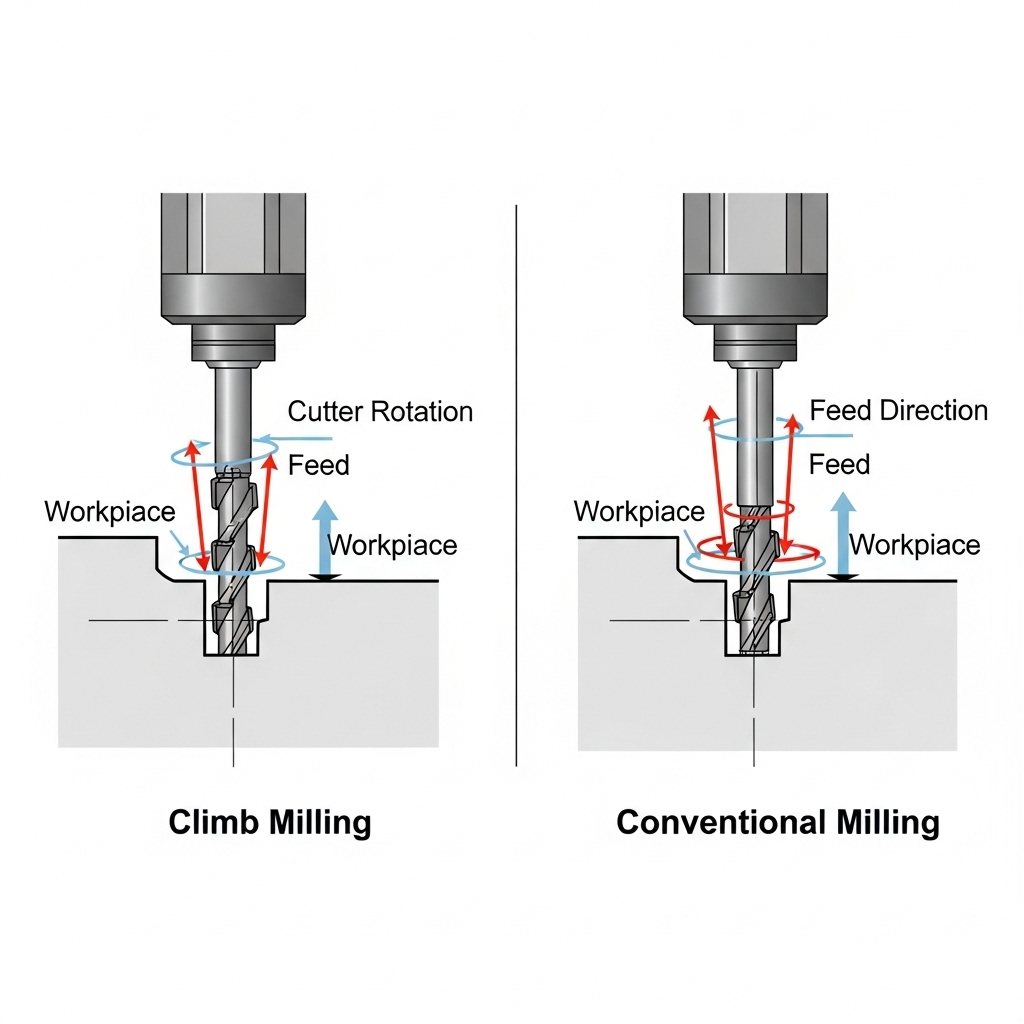

3. Master Climb vs. Conventional Milling

Understanding climb milling versus conventional milling can make a huge difference in tool life and part quality. Climb milling tends to produce better finishes and is preferred in modern CNC environments, while conventional milling can help with machines that have backlash or manual controls.

4. Use Proper Workholding

Even the best strategy will fail if your part isn’t held securely. Always inspect your vise, fixtures, and clamps. Loose setups can cause vibration, poor accuracy, and tool breakage.

Pro Tip: Avoid overhanging setups use the shortest tool and most compact clamping setup possible.

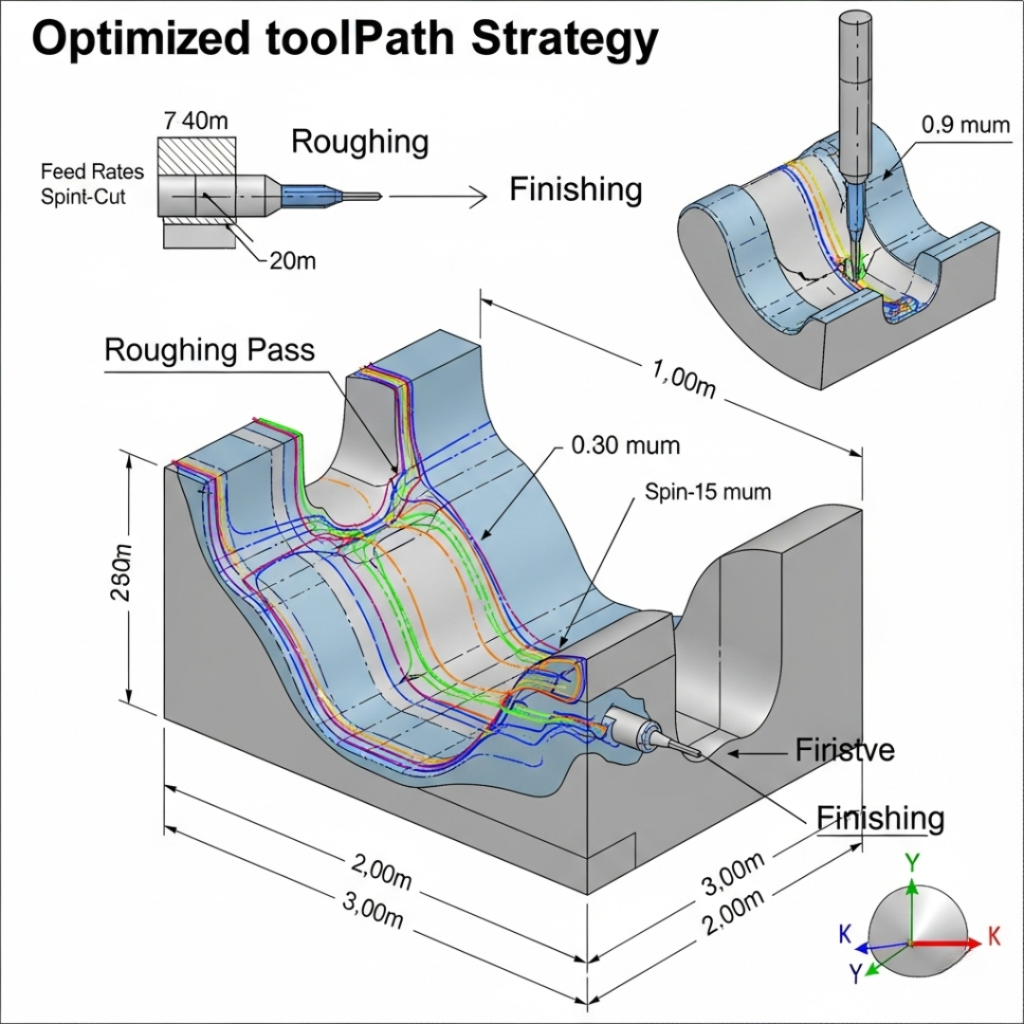

5. Plan Your Toolpaths Efficiently

Don’t just jump in and start cutting. Optimize your toolpaths to avoid unnecessary moves and minimize tool changes. Use roughing passes to clear material and finishing passes for accuracy and surface finish.

Bonus: High-efficiency milling (HEM) strategies can reduce cycle time and improve tool life, especially in hard metals.

6. Maintain Sharp Cutting Tools

Dull tools don’t just give bad results they can damage your machine or part. Keep an eye out for signs of wear like increased spindle load, unusual sounds, or heat discoloration. Replace or regrind tools before they fail.

7. Use the Right Coolant or Lubricant

Coolant isn’t just about keeping the tool cool it also improves chip evacuation and surface finish. Use flood coolant for most metals, mist for light cuts, and air blasts for dry materials or shallow passes.

Quick Note: Aluminum is prone to chip welding, so make sure you have sufficient lubrication.

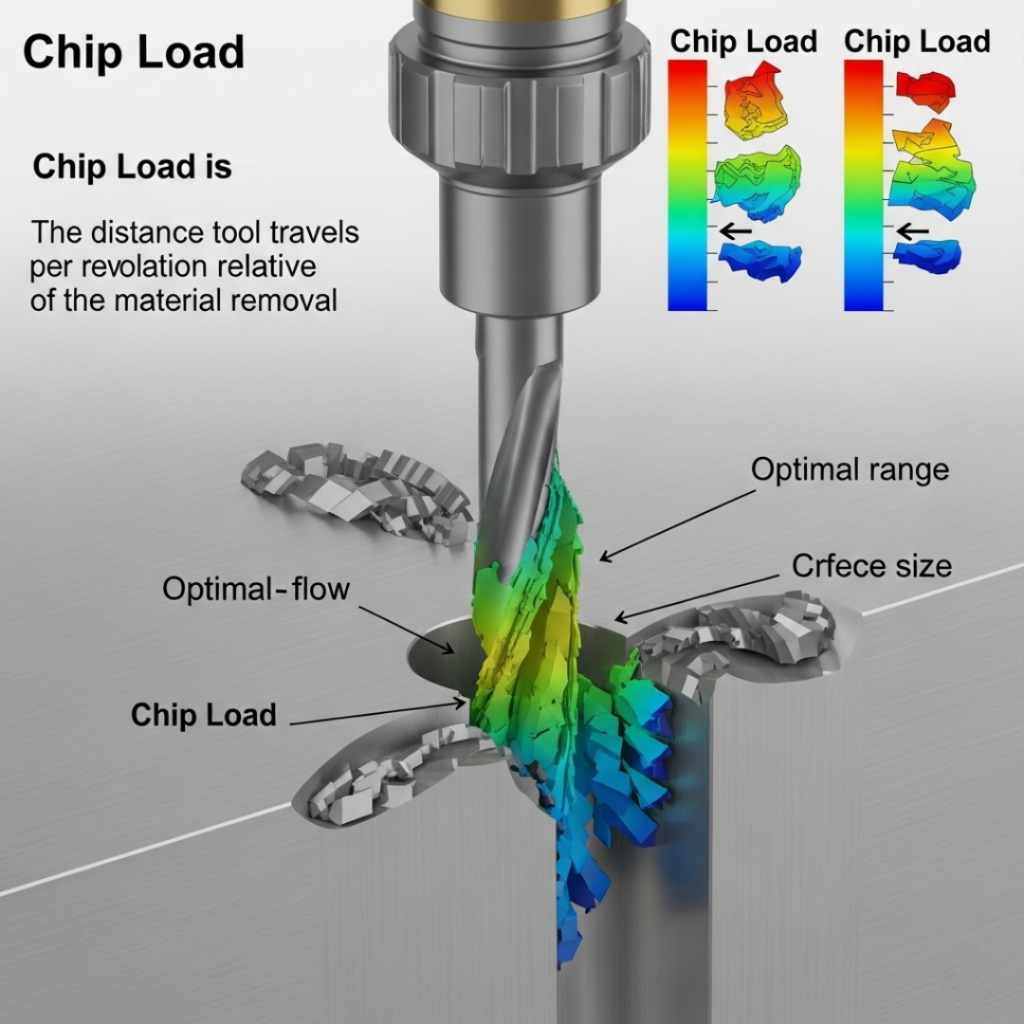

8. Watch Your Chip Load

A consistent chip load ensures your tools last longer and your parts turn out cleaner. Too light a load causes rubbing, while too heavy a load can cause breakage or deflection. Adjust your depth of cut and feed rate to stay within safe limits.

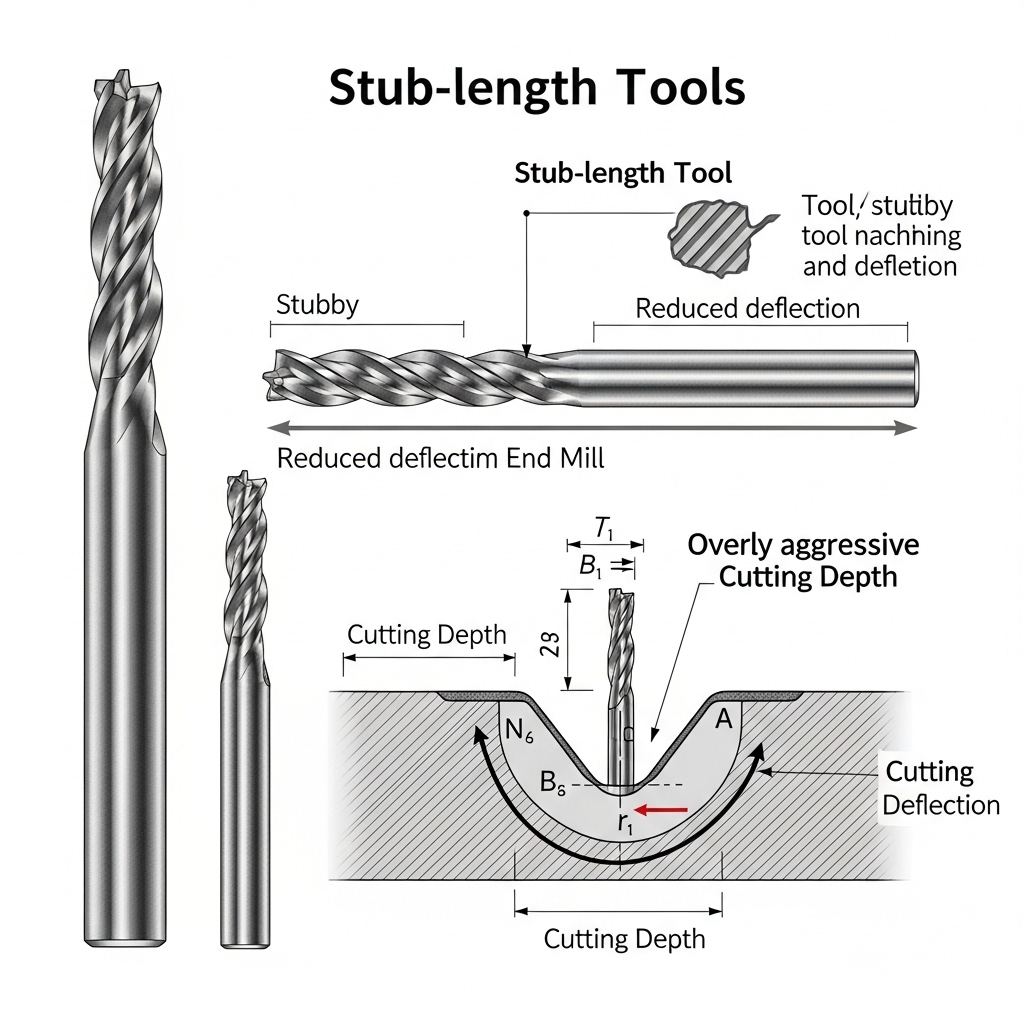

9. Minimize Tool Deflection

Tool deflection leads to poor tolerances and uneven surfaces. Use stub-length tools when possible and avoid overly aggressive cutting depths that may cause the tool to bend or flex.

10. Inspect and Improve Continuously

Every part is an opportunity to improve. Always inspect finished parts for dimensional accuracy and surface quality. Use micrometers, calipers, or a CMM to verify tolerances. Then review your process what worked well, what could be better.

Whether you’re working on a one-off prototype or running a full production batch, these milling tips and tricks can help you reduce waste, avoid costly errors, and produce better results. Staying sharp in your approach just like your tools can make all the difference. For trusted machining tools, expert advice, and industrial solutions, partner with Can Star Industrial helping machinists get the job done right every time.