Band Saw Blade Types: The Ultimate Guide for Industrial Cutting Precision

When it comes to making clean, accurate cuts in wood, metal, and other materials, knowing your band saw blade types can make all the difference. Whether you’re cutting structural steel in a fabrication shop or slicing through hardwood in a mill, choosing the right blade directly impacts performance, safety, and cost-efficiency.

In this guide, Can Star Industrial breaks down the most common types of band saw blades used across industries and helps you match the right blade to your application.

What Are Band Saw Blade Types?

Band saw blade types refer to the different tooth patterns, materials, and configurations used in blades designed for cutting specific materials. Each blade type serves a distinct purpose, offering variations in speed, precision, chip removal, and durability.

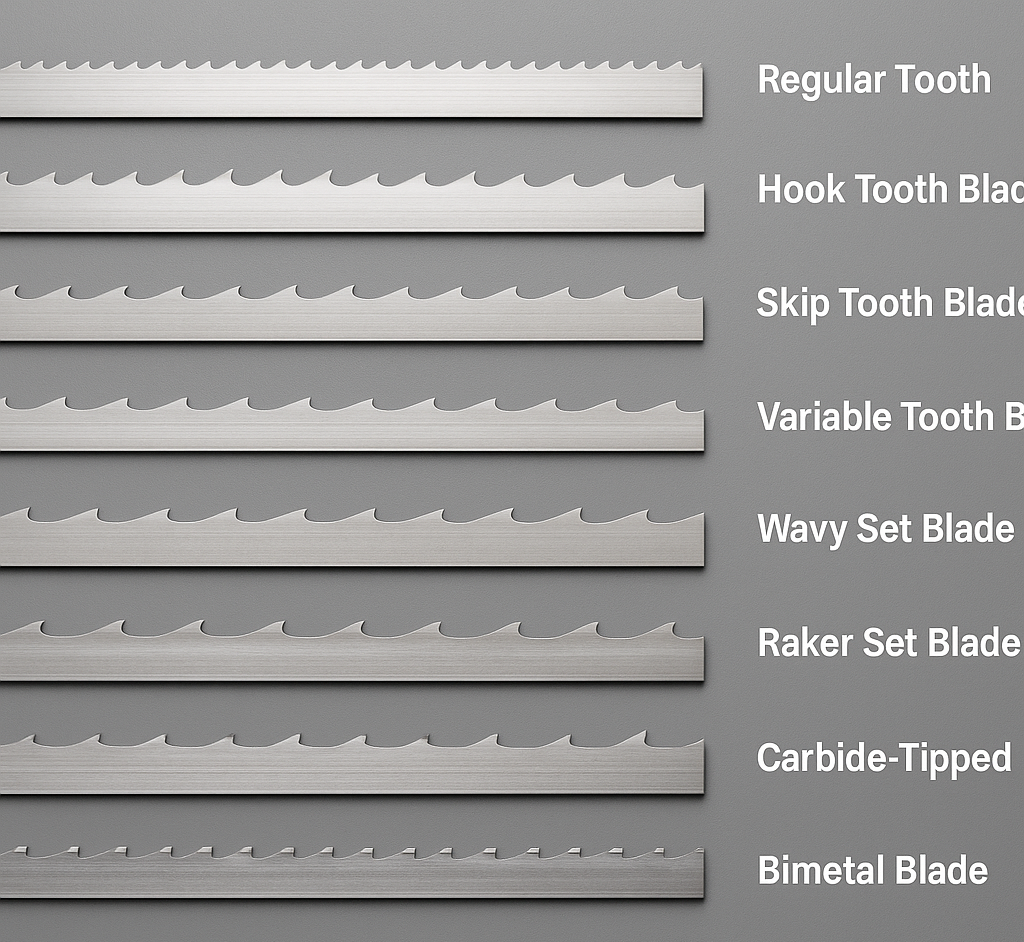

1. Regular Tooth Blade

Best for: General-purpose cutting of wood, soft metals, and plastics

Features:

-

Evenly spaced teeth

-

Deep gullets for efficient chip removal

Ideal Use: Perfect for making smooth, straight cuts on thin materials. This is a go-to blade for hobbyists and professionals alike.

2. Hook Tooth Blade

Best for: Hardwoods, plastics, and non-ferrous metals

Features:

-

Larger teeth with a positive rake angle

-

Deep gullets for aggressive chip removal

Ideal Use: Ideal for resawing thick stock or making fast cuts where precision is still critical.

3. Skip Tooth Blade

Best for: Softwoods and low-density materials

Features:

-

Wide tooth spacing

-

Shallow gullets to prevent clogging

Ideal Use: Reduces friction and heat buildup. Great for curved cuts or intricate designs in soft material.

4. Variable Tooth Blade

Best for: Metal cutting and high-vibration applications

Features:

-

Alternating tooth spacing and sizes

-

Reduces noise and vibration during cuts

Ideal Use: Excellent for irregular stock or when smooth, quiet operation is needed in production environments.

5. Wavy Set Blade

Best for: Thin sheet metals, tubing, and pipes

Features:

-

Teeth set in a subtle wavy pattern

Ideal Use: Provides cleaner finishes without snagging, especially useful when working with fragile or hollow materials.

6. Raker Set Blade

Best for: Thick, solid materials (wood or metal)

Features:

-

Teeth arranged in a “left-right-straight” repeating pattern

Ideal Use: Balanced chip removal and accurate straight cuts. Great for heavy-duty sawing jobs.

7. Carbide-Tipped Blade

Best for: Hard or abrasive materials (e.g., stainless steel, composites, ceramics)

Features:

-

Carbide tips welded to each tooth for durability

Ideal Use: Outperforms traditional steel blades in heat resistance and longevity. A must for high-stress industrial use.

8. Bimetal Blade

Best for: Industrial-grade and heavy-duty metal cutting

Features:

-

High-speed steel teeth fused to a flexible steel backer

Ideal Use: The preferred blade for professional shops dealing with hardened metals. Delivers extended blade life and reduced replacement costs.

Why Blade Type Matters

Using the wrong band saw blade type can lead to:

-

Poor-quality cuts

-

Premature blade wear

-

Increased risk of injury

-

Higher operational costs

Matching the blade to the material ensures:

-

Longer blade lifespan

-

Cleaner, faster cuts

-

Safer operation

-

Better efficiency and productivity

Quick Band Saw Blade Selection Tips

-

Cutting Wood? Use skip or hook tooth blades.

-

Cutting Metal? Choose variable, bimetal, or carbide-tipped blades.

-

Precision Needed? Opt for regular tooth or raker set blades.

-

Thin Materials? Wavy set blades reduce snagging and distortion.

Shop Band Saw Blades at Can Star Industrial

Ready to upgrade your cutting performance? Explore our full line of premium band saw blades suited for wood, metal, composites, and more.

Why Trust Can Star Industrial?

At Can Star Industrial, we understand the unique demands of the Canadian fabrication and manufacturing industries. We offer a wide selection of high-performance band saw blade types designed to withstand tough environments while delivering superior results.

From custom blade solutions to expert support, our team helps businesses choose the right blade for every cutting application.